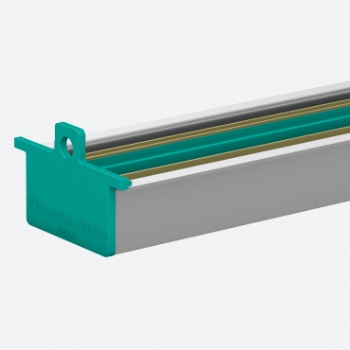

ASCO SCE210G127 Solenoid Valves of series 210, Stainless steel, 230V AC 50Hz

ASCO SCE210G127 Solenoid Valves of series 210, Stainless steel, 230V AC 50Hz, Pipe size 1 1/2”, Orifice size 32mm, Min.0.35bar, Weight 2.4kg.

ASCO SCE210G127 Solenoid Valves of series 210, Stainless steel, 230V AC 50Hz, Pipe size 1 1/2”, Orifice size 32mm, Min.0.35bar, Weight 2.4kg.

Features and Benefits

• Two way shut-off valves for automatic control of air, inert gas, water, oil and other

gases/liquids compatible with the seal materials used

• Valves require a minimum ∆P of 0.35 bar

• All products are covered by Pressure Equipment Directive 2014/68/EU and are suitable

for group 1 and 2 fluids

• The solenoid valves satisfy all relevant EU Directives

General

Differential pressure See «SPECIFICATIONS» [1 bar =100 kPa]

Maximum viscosity 65 cSt (mm2/s)

Response time 15 - 60 ms (3/8” to 3/4”); 40 - 120 ms (1” to 2”)

Materials of components in contact with fluid

() Ensure that compatibility of materials in contact with fluids is verified.

Body Brass / 316L Stainless steel

Shading coil Copper / Silver

Core tube Stainless steel

Core and plugnut Stainless steel

Springs Stainless steel

Seat Brass / 316L Stainless steel

Seal, diaphragm & disc NBR

Piston Brass / st. steel

Piston disc NBR

Disc holder (NO function) PA

Electrical characteristics

Coil insulation class F

Connector Spade plug (cable Ø 6-10 mm)

Connector specification ISO 4400 / EN 175301-803, form A

Electrical safety IEC 335

Electrical enclosure protection Moulded IP65 (EN 60529)

Standard voltages DC (=) : 24V - 48V

(Other voltages and 60 Hz on request) AC (~) : 24V - 48V - 115V - 230V/50 Hz

() Ensure that compatibility of materials in contact with fluids is verified, DC only should be left out at Floating piston construction

(1) Max. operator ambient temperature range (TS) 60°C, DC only

(2) Floating piston construction

Options

• Valves can also be supplied with FPM (fluoroelastomer), EPDM (ethylene-propylene), CR (chloroprene) and PTFE seals and

discs. Use the appropriate optional suffix letter for identification.

• Waterproof enclosure with embedded screw terminal coil according to protection class IP67, CEE-10

• Explosionproof enclosures for use in zones 1/21-2/22, categories 2-3 to ATEX Directive 2014/34/EU (3)

• Electrical enclosures according to “NEMA” standards are available

• Compliance with “UL”, “CSA” and other local approvals available on request

• For protection against corrosion caused by the environment or the fluid, contact us

• Mounting brackets (3/8” to 3/4” solenoid valves)

• Other pipe connections are available on request, pipe identifier 8 = NPT

• Connector with visual indication and peak voltage suppression or with cable length of 2 m (3) Please consult the quick selection guide on potentially explosive atmospheres on Emerson.com/ASCO

Installation

• The solenoid valves can be mounted in any position without affecting operation

• Pipe connection identifier is E = Rp (ISO 7/1)

• Installation/maintenance instructions are included with each valve

ASCO series 210 related model:

SCE210D401

SCE210C006

SCE210D402

SCE210C007

SCE210D409

SCE210D003

SCE210D404

SCE210D008

SCE210G125

SCE210D022

SCE210G127

SCE210-100

SCE210G129

SCE210C013

SCE210D414

SCE210D018

SCE210A131

SCE210D032

SCE210A132

SCE210-103

SCE210A133

Categories

Contact Us

- +86 18707191039

- +86 18707191039

- info@fawoauto.com

- +8618707191039